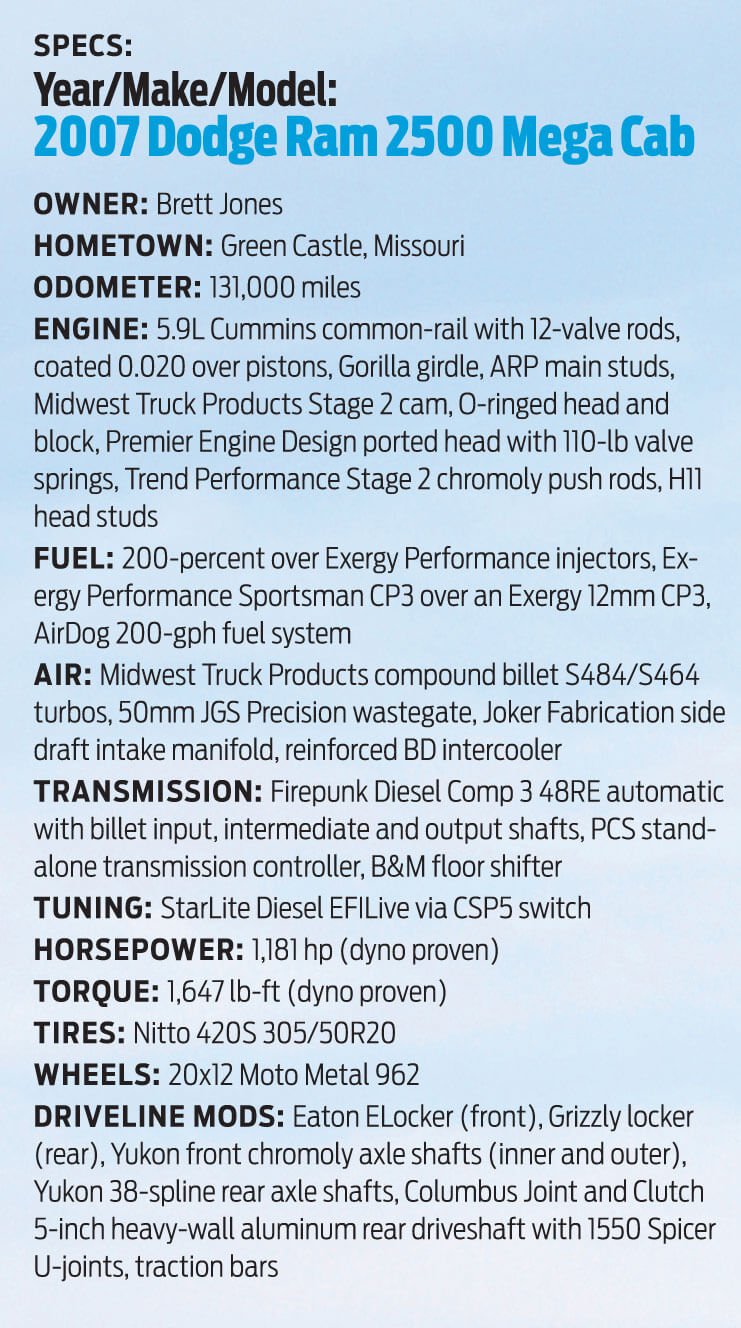

While it’s true that achieving horsepower is addicting and that you can never have enough, most enthusiasts—either voluntarily or involuntarily—draw the line at some point. Then there are diesel head enthusiasts like Brett Jones. In just four years, he’s outgrown a 650hp setup, an 800hp combo, the 940hp mark and now owns a truck with almost 1,200hp.

With the family cattle farm (in addition to being a full-time union electrician), Brett wanted a Ram with Cummins power under the hood; he was also fond of manual transmissions, but when he located this ’07 Mega Cab a few years back and it was equipped with a G56 six-speed, plans for a simple family vehicle were left behind.

Early Modifications

The first modifications were an S475 compound turbocharger overstock arrangement, headstuds, fuel and clutch upgrades. After a while, the truck had 650hp. But the need for more power prompted the addition of more fuel. The factory G56 transmission was destroyed shortly after. Brett decided to cryogenically treatment his next G56 and realized that it was a good time to reinforce the bottom before pushing things further.

“…all hell broke loose in the power department. The truck now makes 1,181hp and 1,647 lb-ft of torque at the rear wheels.”

Midwest Truck Products, in Cantril Iowa, was visited to devise a plan to build a 5.9L that is competition-ready on a budget. ARP main screws and an Industrial Injection Gorilla girdle were also approved, as well as a balanced 12-valve rod set. Mahle pistons in cast aluminum, thermally coated on top and with dry film lubricant applied to the skirts received the go-ahead. The last order of business in the block was the addition of Midwest’s Stage 2 camshaft in place of the factory unit.

The block and the head were both cut to accept O rings for maximum combustion sealing and long-lasting street durability. Premier Engine Design ported the head as far as it could go for a common-rail and kept its water jackets. After that, the head was fitted out with 110-pound valves springs as well as oversize valves. A1 Technologies provided the 12mm H11 bolts to fasten the head onto the block.

FUEL COMPOUNDS AND MORE

Midwest Truck Products’ S400 turbochargers can produce 80psi. Both turbos have billet compressor wheels. The manifold unit has a 64mm wheel and the atmospheric charger an 84mm. The S484 is fed by an external wastegate located on the exhaust system rather than vented to the atmosphere. The first mods to fuel the S484 were a set 100-percent overinjectors from Exergy Performance and a CP3 12mm.

“Both the block and head were cut to accept O-rings for utmost combustion sealing and street longevity.”

The combination of the latter parts resulted in 936hp when tested on a chassis dyno. Then, a set of 200-percent over Exergy Performance injectors, a Firepunk Diesel 48RE automatic, a 200-gph AirDog fuel system, and a second CP3 was added, and as you can imagine—all hell broke loose in the power department. The truck is now capable of 1,181hp, and 1,647lbft at the rear axle.

From top to bottom, Brett’s Dodge was built to handle the whopping amounts of horsepower and prevent catastrophic failure to the engine: Adding front and rear lockers, stronger axle shafts, 1550 series rear U-joints, and a Firepunk Diesel 48RE helps push out four-digit horsepower safely. While it’s never safe to say any 1,200hp truck is indestructible, we’re pretty confident that Brett’s Mega Cab is as close as it gets. DW

“I had the G56 internals cryo’d and was told it would hold 1,000hp—but I knew I was eventually going to be making more than that.” —Brett Jones.

The post Unleashing the Beast: Brett Jones’ 1,200hp Dodge Ram Cummins Build appeared first on Diesel World.