By preventing leaks, you can fix hull moisture issues. Duncan Kent describes how to prevent and fix hull moisture.

Photo: Yachting Monthly cracked caulking Photo: Yachting Monthly

It is rare to find a boat that has no hull moisture.

Sealant on deck gear and sealant on the boat’s hull will begin to dry and shrink with age. Stress cracks may also develop in bad conditions.

Then, before you know it there’s water in the bilge. Even without a leaky boat there’s always condensation to consider.

The gelcoat is osmotically blistered by water. Photo: Yachting Monthly

Owners and buyers are most concerned with osmosis when they consider purchasing an old GRP yacht.

Osmosis is a problem that can become more serious if not treated in a timely manner.

It is important to treat any blisters that you may have before they become more serious.

What causes hull moist via osmosis?

Osmosis occurs when water molecules and solvent molecules migrate through a semipermeable membrane, such as the laminate of a GRP boat.

As the hydraulic pressure in the laminate increases, this hull moisture can cause blisters.

As the GRP fibres break apart under osmotic force, visible blisters can form between the outer layers and the gelcoat surface.

If not treated immediately, hull moisture can cause a vessel to sink. Photo: Yachting Monthly

Water ingress can cause osmosis on GRP boats. However, it may also be due to impurities found in the resin, or in the catalytic chemical used to cure them.

This stray element can react with moisture in the laminate and form expanding bubbles of mixed chemical mixtures. These can develop even within a few year of a boat being launched.

The GRP surface of other parts can also become osmosis-prone, usually when moisture has been trapped in the laminate.

The area under gas canisters or life rafts/dinghys in a locker is often a culprit.

The bilges are another common place, especially around a GRP tank.

How does osmosis start?

Some polymer-based materials are permeable by water, particularly salt water. These include the resins that make up the gelcoat or laminate composite of GRP boat hulls.

Over time, water is absorbed by the gelcoat and then diffuses through the fibre laminate. The water diffusion rate increases with the original quality of the laminate.

Osmosis can be tested by puncturing blisters. If they drain liquid, usually with a pungent smell of vinegar, then it’s probably osmosis. Photo: Yachting Monthly

Boatbuilders often scrimped on resin when wetting out the boat during the oil crisis of the 1970s.

This frequently left voids and ‘dry’ patches throughout the laminate that acted like blotting paper to any inherent moisture in the hull and were often the starting point for the creation of an osmotic blister.

Technically known as hydrolysis (or osmotic reaction), the osmotic method creates a large concentration of dissolved chemical in the void. This, coupled with the fact that the membrane is hydroscopic in nature, causes it to encourage more water through to try and equalise acidity.

Sometimes it’s not a large area, but merely tiny spots of hull moisture where the resin hasn’t been rolled in fully and the laminate thoroughly wettened.

They can be fixed using non-invasive techniques, but deep voids can cause the hull’s delamination. This can lead to a high level of risk.

The vessel is actually sinking.

Resins

Osmosis occurs more frequently in GRP boat built between 1970-2000.

This was primarily due to the older orthophthalic polyesters used, which are more susceptible to moisture penetration than the isophthalic resins that were used in the majority of post-2000 constructions.

Boatbuilders began to use more vinylester resins (polyester/epoxy) which, although more expensive, resulted in a composite that was more durable and water resistant.

The hull is treated by removing the gelcoat. Photo: Yachting Monthly

Epoxy is the resin that is most resistant to osmosis. It’s used extensively in the automobile and aeronautics industries as well as yachts.

Many boatbuilders now apply an epoxy barrier primer to the bare gelcoat before any antifouling coating, which greatly increases the hull’s resistance to moisture ingress.

It is not necessary to use a thick layer of epoxy resin to waterproof a composite boat. A thin coating is sufficient to provide excellent protection.

If you are applying epoxy to an older hull that has been stripped of its gelcoat, it is important to make sure the hull is completely dry before applying the epoxy. Otherwise, moisture can be trapped inside the laminate and cause further problems.

It is a more expensive option, but it requires very specific ratios as well strict environmental conditions when mixing and applying.

How to prevent and treat hull moisture

When a boat experiences a significant change in temperature (for example, after spending most of its time in the cold waters of northern Europe, but then being moved), osmosis can occur.

The warmer waters in the Caribbean and the Mediterranean.

A GRP hull will often be high in moisture content but not necessarily have, or be about to suffer from osmosis, although it’s often an indication of problems to come.

Older and thicker solid GRP hulls tend to be able to absorb more water without getting osmosis, but it’s still advisable to store a GRP boat ashore to dry out for a few months each year, where possible.

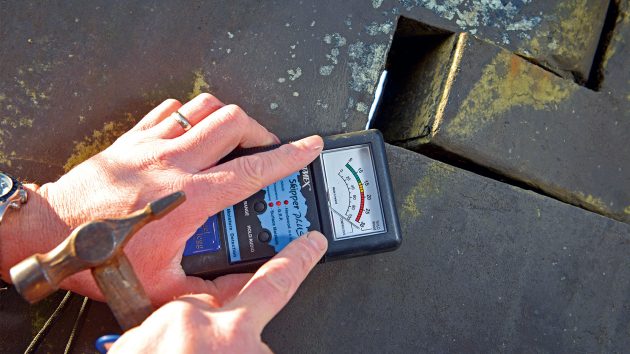

You can determine the extent of osmotic issues with a moisture meter. Photo: Yachting Monthly

You can test for acidity by puncturing the blisters and testing their liquid with litmus paper.

You will then need to use a moisture meter to measure the damage done to the hull.

If it’s only a few blisters over a small area you can usually just dig these out after lifting the boat ashore, wash the cavities well with fresh water and then leave to dry for a few months.

A curtain should be placed around the repair site if you’re working outside. Heat may be needed to remove moisture. If possible, you should put it in a heated boatshed for a couple of weeks.

Once completely dried out, cavities can be filled in and smoothed. The area can then be repainted.

Photo: Yachting Monthly Photo: Yachting Monthly

If, however, large areas or the whole hull is blistered, you’ll need an expert’s opinion.

If it’s really bad there’s no other option than a full gelcoat strip followed by systematic treatment of the entire hull below the waterline.

Spongy decks

Spongy decks are a common problem with older GRP yachts.

Between the 1970s-90s many boats had balsa-cored sandwich decks, partly to make them stiffer, and partly to help reduce the boat’s weight above the waterline.

Divinycell foam core, a PVC foam with a closed-cell density, is commonly used on both the topsides and decks of modern ships.

In good condition, the modern foam sandwich is completely waterproof, whereas the earlier ‘end-grain’ balsa or plywood cores certainly weren’t.

Water can slowly rot wood if the seals are not good around the deck fittings.

Even when you buy a new deck, it is important to check for any leaks.

If kept dry, balsa-cored laminate sandwich panels will remain robust and strong. Photo: Yachting Monthly

So, when you’re looking over a boat with the idea of buying it, tread carefully all over the decks, especially around any fittings, checking for ‘give’, or sponginess in the deck.

You may hear squelching noises and see water seeping from cracks in the fittings, such as stanchion base.

Buy or borrow a humidity meter and learn how to properly use it. Then check the entire deck yourself for readings of high moisture.

Article continues below…

Expert advice on boat maintenance

It may not be anyone’s favourite thing to spend their time doing, but boat maintenance is crucial for any boat…

Best boat dehumidifier: 11 models to keep your boat dry

Boats tend to thrive in damp environments. Even if you keep yours ashore or in…

Teak decking

On older yachts that had teak decks, the wooden planks would be screwed into the GRP.

The caulk was waterproof and flexible when the planking was new. But after many years, the caulk shrinks and dries, and water will eventually find its way into the laminate beneath.

It’s even worse if the underdeck has a wooden core as well, as this will rapidly turn to mush, making it an even bigger job than simply replacing the teak.

Check for flexing, and listen for squelching sound.

Look for any areas where the caulking has shrunk, or if water may have seeped in.

Backing pads

A common place to check for moisture damage on decks is the areas where backing pads were bonded to the laminate (usually plywood, but sometimes metal plates). These backing pads increased the shear strength of the material beneath heavy deck fittings such as winches or windlasses.

Photo: Yachting Monthly. Winch reinforcements are vulnerable to long-term stress. Photo: Yachting Monthly

Under repeated stress, the area around the pads can crack and water will seep in.

If they’re plywood, which is common, they will rot and very often disintegrate. Metal can oxidise, causing the laminate to separate from it.

Both can allow moisture to seep into the GRP, creating an area of even greater structural instability.

Hull damage

When berthing during high winds, hulls with cores between the waterline & deck may suffer minor damage.

The Etap 28 is one of many yachts that are constructed with an internal moulding for extra buoyancy and insulation. Photo: Yachting Monthly

The most common concern with foam sandwich hulls is that the core can become de-bonded from GRP outer skin. This is often caused by excessive flexing or physical damage to the laminate.

When this occurs, the structure loses its shear strength. The hull will start to crack and water can enter the cavity between core and skin.

The gap between the inner moulding of the boat and its outer skin is filled with polyurethane expanding foam, which provides additional buoyancy.

The gelcoat can be polished after a successful hull repair. Photo: Yachting Monthly

Although the foam doesn’t absorb or wick moisture, there have been a few cases of the foam inside breaking away from the outer skin, causing it to flex and crack, letting water seep in.

The moisture is usually caused by collision damage on the hull.

Saturated sandwich deck

While damp decks are quite common in older boats it’s not necessarily a reason for not buying it.

Unless you’re an expert, you will need to have it thoroughly checked/metered out and maybe some core samples taken to assess just how bad the condition is.

If the laminate deck on either side is free of osmosis then the core can be easily replaced.

For a quick repair, or bodge in real life, you will usually need to drill holes in your deck and inject resin into areas that are not overly damaged or close to high-stress zones.

While this may stop the deck from flexing so much, it doesn’t really solve the problem and should really only be done as a temporary fix, as it adds little extra structural strength to the deck area being treated.

The core will start to get soaked sooner or later and begin to cause osmosis. Water left in the core will also expand and freeze, causing the resin bond to break and a larger repair bill.

The osmotic blister is easily treated, but if left untreated for too long it can lead to serious damage. Photo: Yachting Monthly

It is best to remove the entire core by cutting one side, removing it, replacing it with closed-cell sheets of foam, then re-laminating the top.

It’s hard to make such a drastic repair invisible from on deck, so repairing it from the inside after removing the headlining can be aesthetically better. This is a more difficult way to repair the headlining.

If an area has been waterlogged for a long time, there’s a good chance the laminate might be damaged as well, making the whole area structurally unsound.

It is possible that the repair work would be too expensive to justify.

When repairing rotten plywood backing pads under winches or deck gear it’s often better to bond in some very tough, polyethylene foam pads, or use an extra thick base of solid GRP.

Fixtures

There are also metal components, like chain-plates that have been laminated.

Photo: Yachting Monthly. The movement of metal fittings may eventually allow water to enter the laminate. Photo: Yachting Monthly

After years of sailing, even a slight movement can cause the laminate to crack, allowing moisture in.

It slowly corrodes the metal, including stainless steel. This creates a serious failure risk.

Once again the only cure is to cut away the GRP, replace the chainplate, and ideally not laminate back over it again so it’s clearly visible and fresh air can get to it.

Old metal fuel and water tanks can also cause problems, especially if they were originally bonded onto the boat.

The bonding will start to separate or split over time, particularly when the tank is full and the conditions are rough.

Even worse, the tabs that secure the hull can rip away the surrounding laminate and allow damp to seep into the hull.

You enjoyed reading it?

Subscription to Yachting Monthly magazine Costs around 40% less than cover price.

Print and digital editions are available through Magazines Direct – where you Find the best deals on our website.

YM offers a wide range of useful information for your boating experience.

-

-

- Experts offer tips, tricks and advice to help you take your sailing skills to the next step.

- Reviews of the latest yachts & equipment, unbiased and in-depth

- Get to your dream destination with our cruise guides

-

Follow us on Facebook, Twitter The following are some examples of how to get started: Instagram.

The post How to fix and find hull moisture on your boat appeared first on Yachting Magazine.