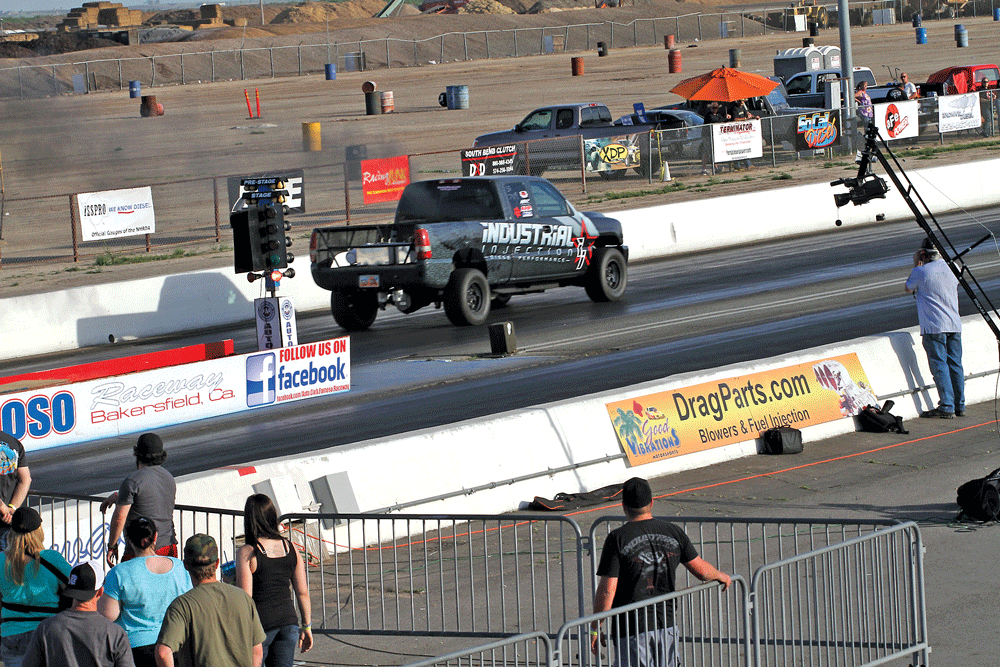

Brett Williams is the Vice President of Industrial Injection, located in Salt Lake City. If you haven’t heard of the crew at Industrial Injection, they’re one of the leading diesel performance experts in the industry today, and this story is about their VP’s diesel, a Duramax drag truck. While it’s not the first diesel he’s ever driven, it’s the first Duramax he’s owned.

Back up

This truck’s story is that its previous owner took it to the shop for repairs. This owner then abandoned his rig because the required repairs were too expensive. The project began with an offer.

The 2001 pickup truck was initially intended as a service vehicle. However, after the teardown, it became apparent that there was more to the issue than just injectors. It was clear from a broken headbolt that the engine would need to be pulled. The former daily car was now on its way to transformation.

Metamorphosis

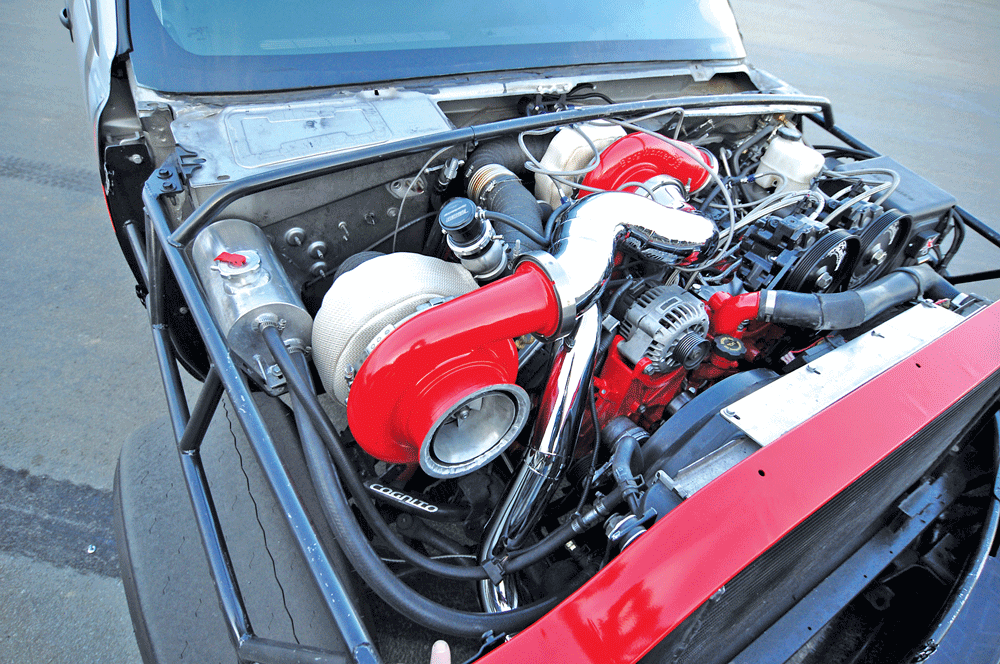

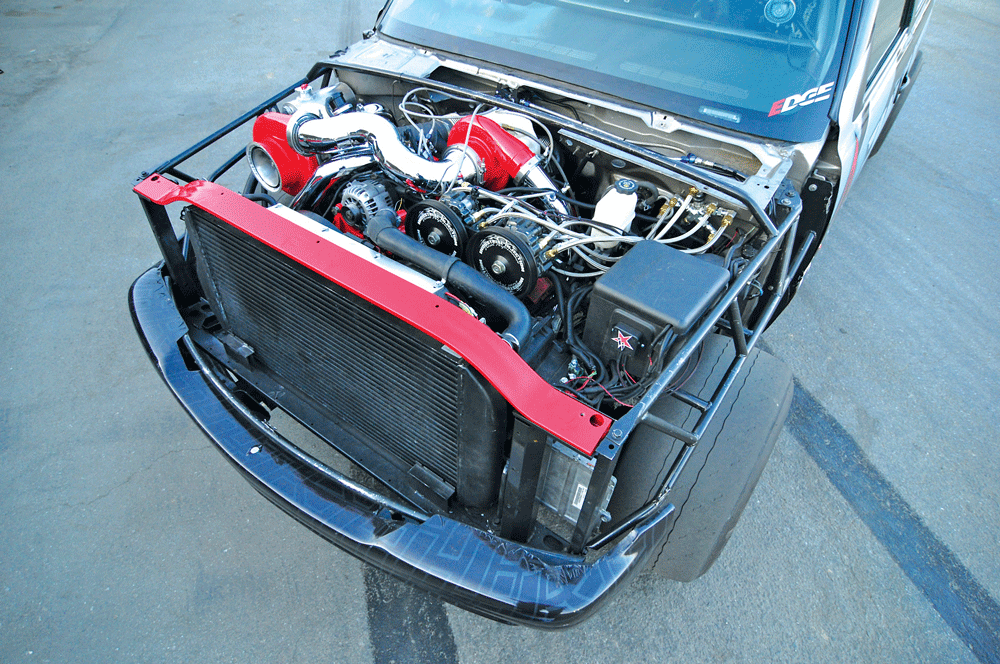

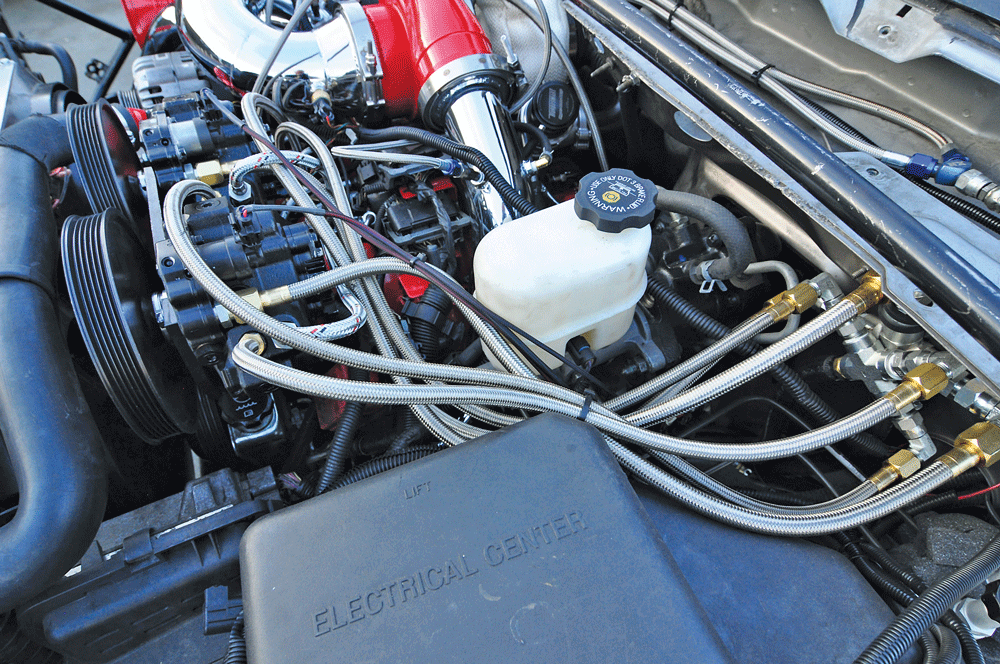

The first thing to do was to build the engine from scratch. It included a Winburg Billet Crank, Carrilo Rods (forged pistons), Industrial Injection Ported Heads with their alternate firing-order camshaft, and some Industrial Injection ported cylinder heads. The 48RE automatic was used to connect the engine to a Sun Coast torque convertor with a 3,500 rpm stall. A Precision air shifter controlled gear selection.

This truck was brought in for repairs by its previous owner. This owner then abandoned his rig because the required repairs were too expensive. The truck was offered for sale, and the project began.

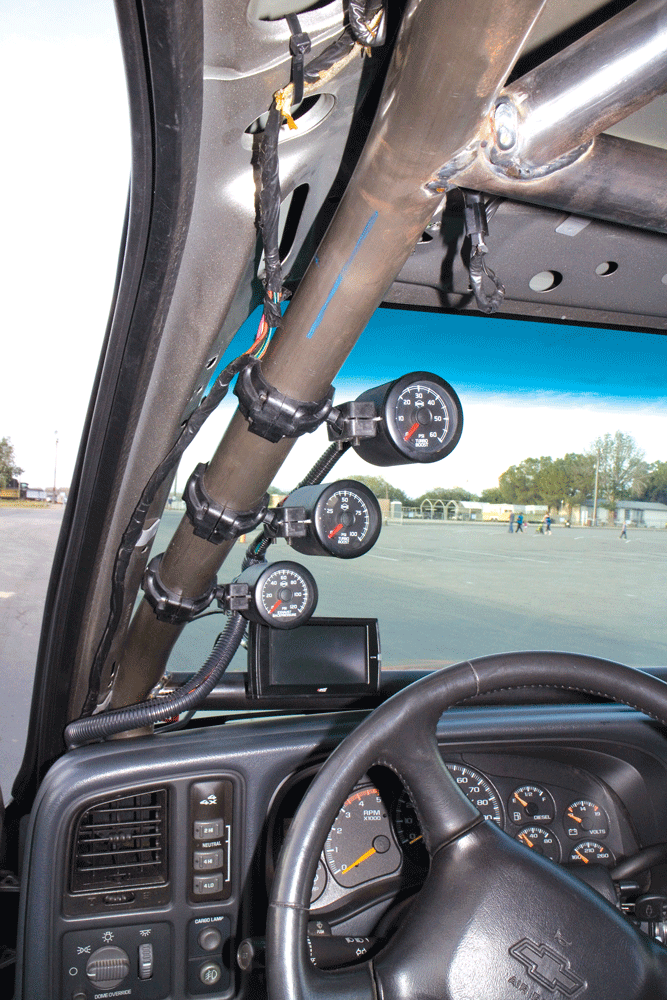

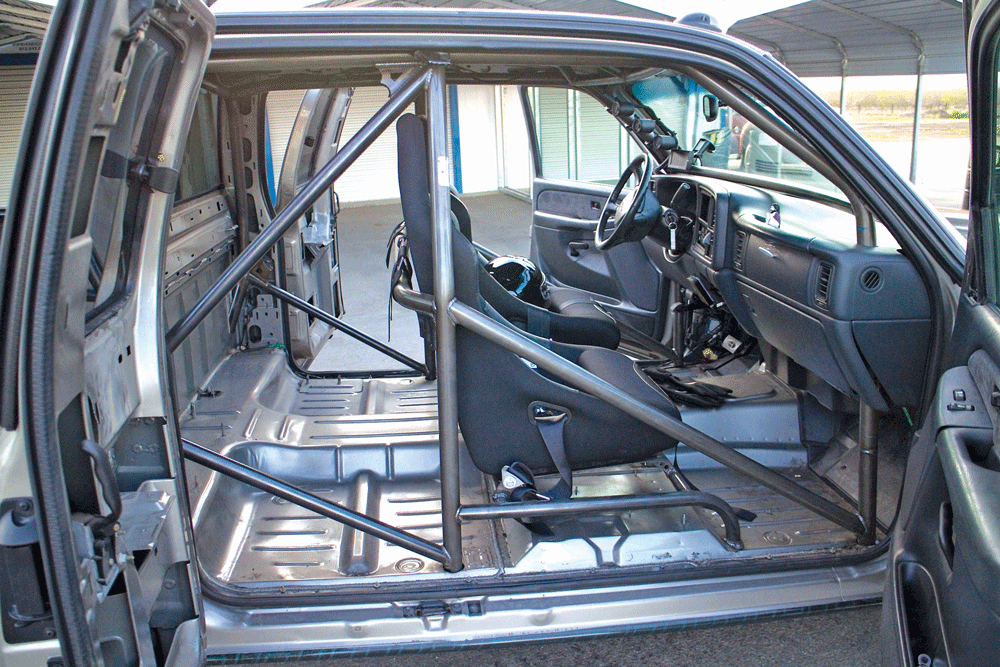

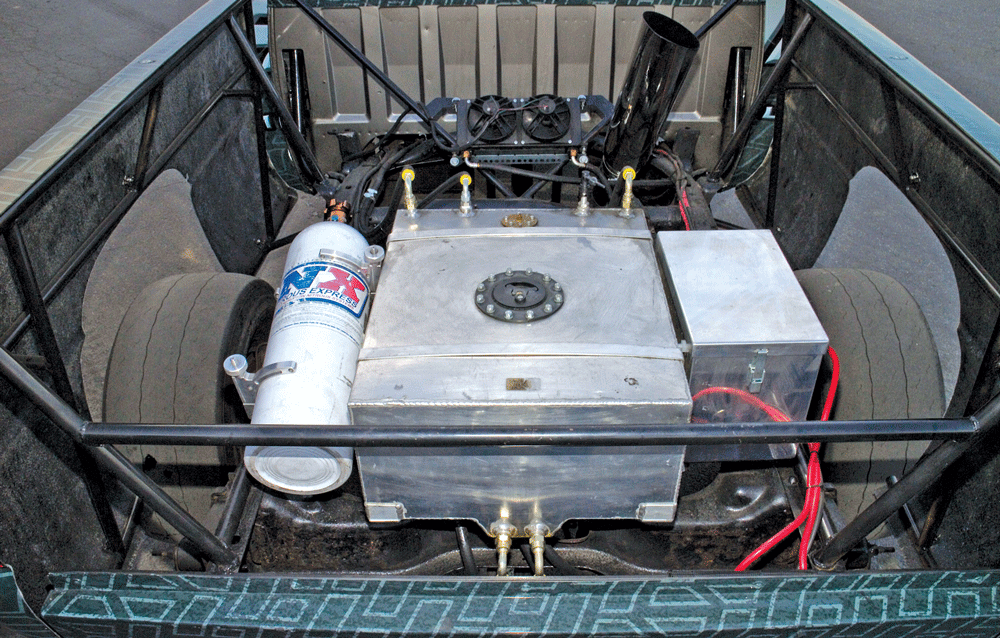

The body was left untouched, except for the dash. The cage was from Rollover Motorsports, and a set Corbeau 5-point belted seats were installed. The truck’s original appearance was retained, as the fiberglass side panels on the bed were used to replace it. A fiberglass hood, front fenders, and other weight-saving methods were also used.

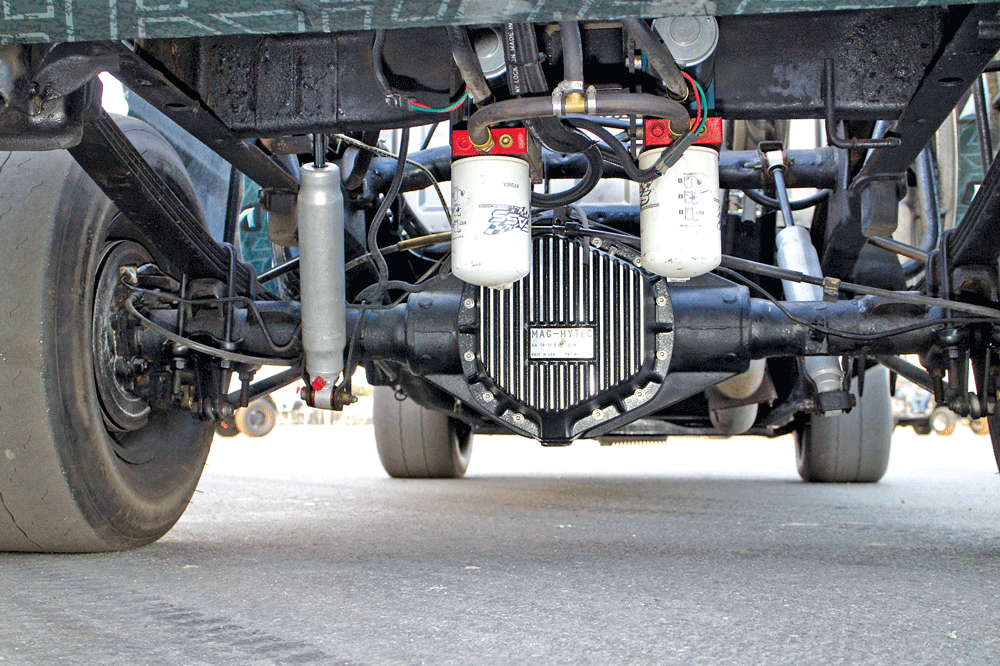

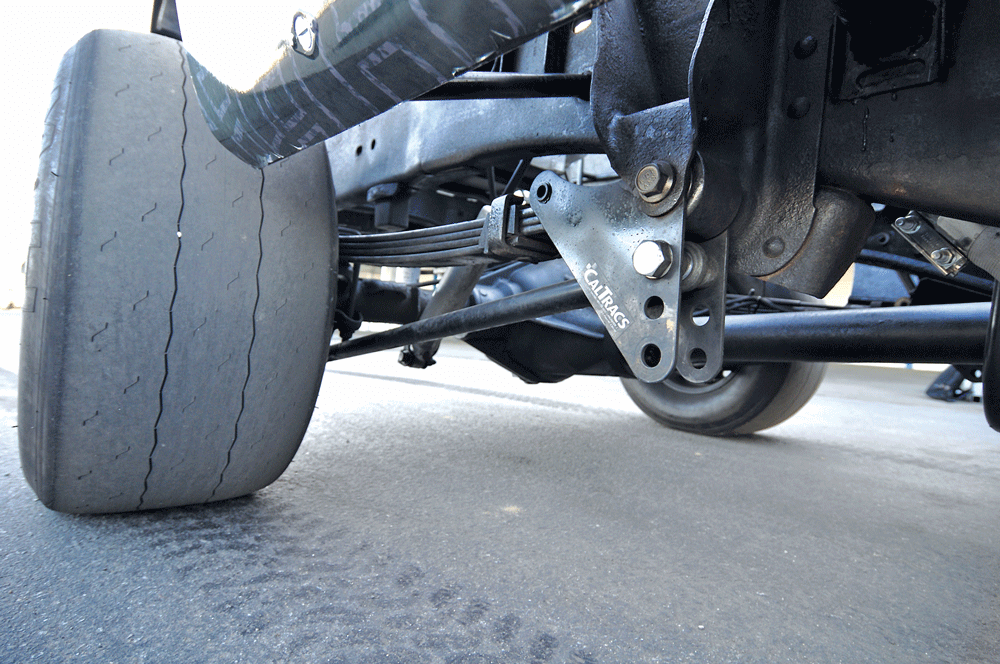

Other upgrades include Rancho shocks and Stainless Steel Brakes tri-power brakes. Cal Trac traction bar, PPE center link, Cognito A-arms and Flex-a Lite cooling fans. Twin FASS 260 gpm pumps were also installed. The team also installed triple Dragon Fire fuel injection pumps, Cobre injectors of 1100 cc, and a Nitros Express System NO2 system. Starlite Diesel made a custom tuning using an Edge cst with ESA and EFI data logger. PPE exhaust manifolds, up-pipes and custom piping are used on the exhaust side.

How Does It Stack Up to the Competition?

This truck can pump out 2,000 horsepower and 3.000 lb.-ft. at 5,000 rpm. The figures above are estimates based upon the fact that the diesel consistently maxes out the Industrial Injection dyno. These numbers are the highest they could accurately record.

Brett was helped by many people in the build: Dallas Hunt, Chavis Fryer and many Industrial Injection employees. Brett was helped by many: Dallas Hunt and Chavis Fryer, as well as other Industrial Injection staff. Now, the team can sit back and enjoy the ride as the truck speeds down the track. With 158 mph as the top speed, ¼ mile ETs at a consistent 9.63 seconds, this truck is a winner. DW

The post Industrial Injection’s VP Unveils a Duramax Drag Truck: A Diesel Powerhouse appeared first on Diesel World.